|

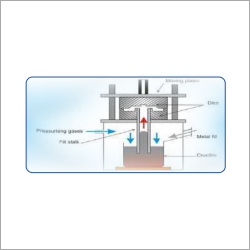

Low Pressure Diecasting Dies

Price 500000 INR/ Pair

MOQ : 1 Pair

Low Pressure Diecasting Dies Specification

- Material

- Steel

- Application

- Automotive and Industrial Component Casting

- Processing

- Low Pressure Die Casting

- Surface

- Polished

- Machining Type

- CNC Machined

- Cooling System

- Integrated water or oil cooling channels

- Casting Alloy Compatibility

- Aluminium, Magnesium, Zinc

- Mold Base

- Standard or Customized

- Core Insert Material

- Tool Steel

- Design Software

- CAD/CAM supported

- Tolerance

- ±0.01 mm

- Cavity Quantity

- Single or Multiple, as per requirement

- Dimensions

- Customized as per client design

- Coating

- Anti-corrosion treated

- Heat Treatment

- Through Hardened and Tempered

- Service Life

- Up to 100,000 shots

- Hardness

- HRC 48-52

- Die Type

- Custom Mould

Low Pressure Diecasting Dies Trade Information

- Minimum Order Quantity

- 1 Pair

- Supply Ability

- 40 Pairs Per Month

- Delivery Time

- 4 Week

About Low Pressure Diecasting Dies

Alloys with low melting points are used in the engineering of Low Pressure Die Casting Dies, thereby, allowing the production of various industrial components weighing around 150 kilograms. The benefits of using the mentioned type of our offered Low Pressure Die Casting Dies includes extreme strength. Moreover, it provides the ability to form complex geometeries while enhancing the material uses of components. The affordability and quality of our offered dies are a couple of reasons that make them the best dies to invest in.

Precision Engineering for Demanding Industries

Our dies are meticulously crafted using high-grade steel and advanced CNC machining, ensuring precision and consistency in every cast. With support for multiple casting alloys and CAD/CAM-integrated designs, clients achieve superior results for both automotive and industrial components.

Enhanced Durability and Extended Service Life

Through hardening and tempering, our dies offer a robust hardness range of HRC 48-52 and include anti-corrosion coatings. This translates to minimized wear and tear, providing up to 100,000 operational shots, making them a cost-effective solution for medium to high-volume production runs.

Customization for Unique Production Needs

Clients can specify single or multiple cavities, standard or customized mold bases, and tailored dimensions. Integrated cooling channelsusing water or oilensure optimum thermal management, while our CAD/CAM expertise brings complex designs to life with precision and efficiency.

FAQs of Low Pressure Diecasting Dies:

Q: How is the durability of your Low Pressure Diecasting Dies ensured?

A: Our dies are manufactured from tool steel, then undergo thorough hardening and tempering, achieving HRC 48-52 hardness. Additionally, an anti-corrosion coating is applied, resulting in a service life of up to 100,000 casting shots under normal operating conditions.Q: What casting alloys are compatible with these dies?

A: These dies are compatible with aluminium, magnesium, and zinc alloys, making them versatile for diverse automotive and industrial applications.Q: When should clients choose a single-cavity versus a multi-cavity die?

A: A single-cavity die is ideal for specialized or low-volume production, while multi-cavity designs are recommended for higher production rates, as they allow simultaneous molding of multiple components, optimizing efficiency and cost.Q: Where can these dies be deployed effectively?

A: They are suitable for automotive and industrial component casting, where tight tolerances, complex geometries, and a robust service life are essential. We supply and export globally, with manufacturing based in India.Q: What is the process for developing a customized die?

A: The process involves collaborative design using CAD/CAM software, where client requirements for dimensions, cavities, and mold base types are incorporated. The die is then precision-machined and finished with integrated cooling channels and specialized coatings.Q: How are thermal management and quality ensured in these dies?

A: Integrated water or oil cooling channels regulate die temperature during low pressure die casting. This not only maintains consistent material properties but also extends die life and ensures high-quality castings.Q: What are the main benefits of using your customized diecasting dies?

A: Clients benefit from tighter tolerances (0.01 mm), superior surface finishes, extended die life, faster cycle times from efficient cooling, and tailored features that best fit their specific production and component needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Die Castings Category

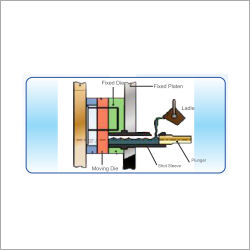

Pressure Die casting Dies

Price 500000 INR / Pair

Minimum Order Quantity : 1 Pair

Processing : Pressure Die Casting Process

Material : Other, Steel, Tool Steel

Machining Type : CNC Machining, EDM

Application : Pressure die casting, Automotive Parts, Industrial Components

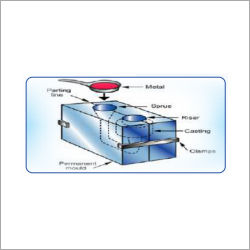

Gravity Die casting Dies

Price 500000 INR / Pair

Minimum Order Quantity : 1 Pair

Processing : Gravity Die Casting

Material : Other, Highgrade Steel Alloy

Machining Type : CNC and Conventional Machining

Application : Automotive Parts Manufacturing, Aerospace Components, Industrial Machinery

|

DIE TECH INDIA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry