|

Gravity Die casting Dies

Price 500000 INR/ Pair

MOQ : 1 Pair

Gravity Die casting Dies Specification

- Material

- High-grade Steel Alloy

- Application

- Automotive Parts Manufacturing, Aerospace Components, Industrial Machinery

- Processing

- Gravity Die Casting

- Surface

- Polished, Anti-corrosive finish

- Machining Type

- CNC and Conventional Machining

- Coating

- Nitrided or Plated options available

- Cooling System

- Integrated Water Cooling Channels

- Dimension Range

- From small to large-sized components

- Mould Maintenance

- Low, with extended service intervals

- Cavity Type

- Single or Multi-Cavity

- Die Life

- Up to 80,000 shots

- Tolerance

- ±0.01 mm

- Hardness

- HRC 38-42

- Weight Capacity

- Up to 200 kg per die

- Design

- Customizable as per Product Drawing

- Production Use

- Suitable for Mass and Batch Production

- Heat Treatment

- Induction and Vacuum Hardened for Durability

Gravity Die casting Dies Trade Information

- Minimum Order Quantity

- 1 Pair

- Supply Ability

- 40 Pairs Per Month

- Delivery Time

- 4 Week

About Gravity Die casting Dies

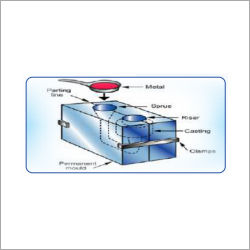

Gravity die casting is considered as the famous process that is developed for metal as well as light alloy die casting. In the discussed process, molten metal form gets poured in the rightful manner from a ladle into a highly perfect semi-permanent or permanent die. We match possible customers needs for Gravity Die Casting Dies in the most advanced manner. The famous die casting technology finds ideal application in several complex aluminum casting manufacturing of important automotive parts like engine cylinder heads, brake calipers, engine blocks as well as pistons, etc. We serve Gravity Die Casting Dies at the attractive prices in expected marketplaces.

Precision and Customization

Each gravity die casting die is custom-designed according to your product drawing, ensuring optimal fit and performance. Our engineering team leverages advanced CNC and conventional machining processes, delivering dies with single or multi-cavity configurations, as per application requirements. The result is enhanced casting accuracy for small and large components alike.

Reliability and Longevity

Our dies are crafted from robust high-grade steel alloys and undergo stringent induction and vacuum hardening to achieve a hardness of HRC 38-42. Coatings such as nitriding or plating provide further durability, resisting wear and corrosion. This engineering results in dies capable of withstanding up to 80,000 shots with minimal required maintenance.

Efficiency for Mass Production

Featuring integrated water cooling channels and a weight capacity up to 200 kg per die, these tools are optimally engineered for both mass and batch manufacturing. Their anti-corrosive finish and extended maintenance intervals ensure smooth, consistent production flows, making them an ideal investment for high-output environments in automotive, aerospace, and industrial sectors.

FAQs of Gravity Die casting Dies:

Q: How does the gravity die casting process benefit from these dies?

A: Our gravity die casting dies are specifically designed to handle repeated thermal cycles, maintaining precision thanks to tight tolerances of 0.01 mm. Their robust construction and efficient cooling system enable stable, high-quality casting, reducing scrap rates and boosting overall efficiency in automotive, aerospace, and industrial manufacturing.Q: What is the die life expectancy and how is it achieved?

A: Each die is designed for up to 80,000 shots, made possible by high-grade steel, advanced hardening treatments, and resilient surface coatings. These features ensure resistance to wear, heat, and corrosion, promoting longevity while maintaining dimensional precision through prolonged production runs.Q: When should maintenance be performed on these dies?

A: Due to their superior construction and low-maintenance design, these dies require servicing at extended intervals. However, maintenance schedules may vary depending on usage intensity and material cast. Regular inspection after certain production cycles is recommended to prolong lifespan and retain optimal performance.Q: Where can these gravity die casting dies be utilized?

A: They are suitable for a wide range of applications, including the manufacturing of automotive parts, aerospace components, and industrial machinery. With customizable dimensions and cavity types, their versatility supports various high-precision mass or batch-production projects.Q: What size and type of components can these dies accommodate?

A: Our dies are adaptable to both small and large-sized components, with options for single or multi-cavity layouts. This flexibility ensures compatibility with diverse product requirements and production volumes, making them suitable for a broad spectrum of casting projects.Q: How does the integrated water cooling system enhance die performance?

A: The built-in water cooling channels regulate die temperature, preventing overheating during casting cycles. This stabilizes material flow and minimizes wear, contributing to longer die life and maintaining consistent quality across extensive production runs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Die Castings Category

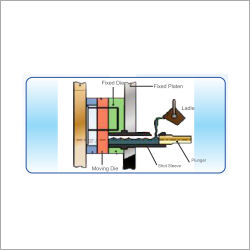

Pressure Die casting Dies

Price 500000 INR / Pair

Minimum Order Quantity : 1 Pair

Application : Pressure die casting, Automotive Parts, Industrial Components

Material : Other, Steel, Tool Steel

Processing : Pressure Die Casting Process

Surface : Other, Polished, Treated, Surface Coated

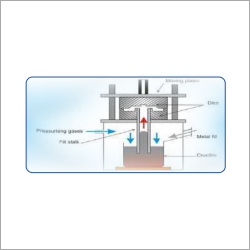

Low Pressure Diecasting Dies

Price 500000 INR / Pair

Minimum Order Quantity : 1 Pair

Application : Automotive and Industrial Component Casting

Material : Steel

Processing : Low Pressure Die Casting

Surface : Other, Polished

|

DIE TECH INDIA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry